Precast Prestressed Ribbed Slabs Using Natural Stone and Reused Concrete

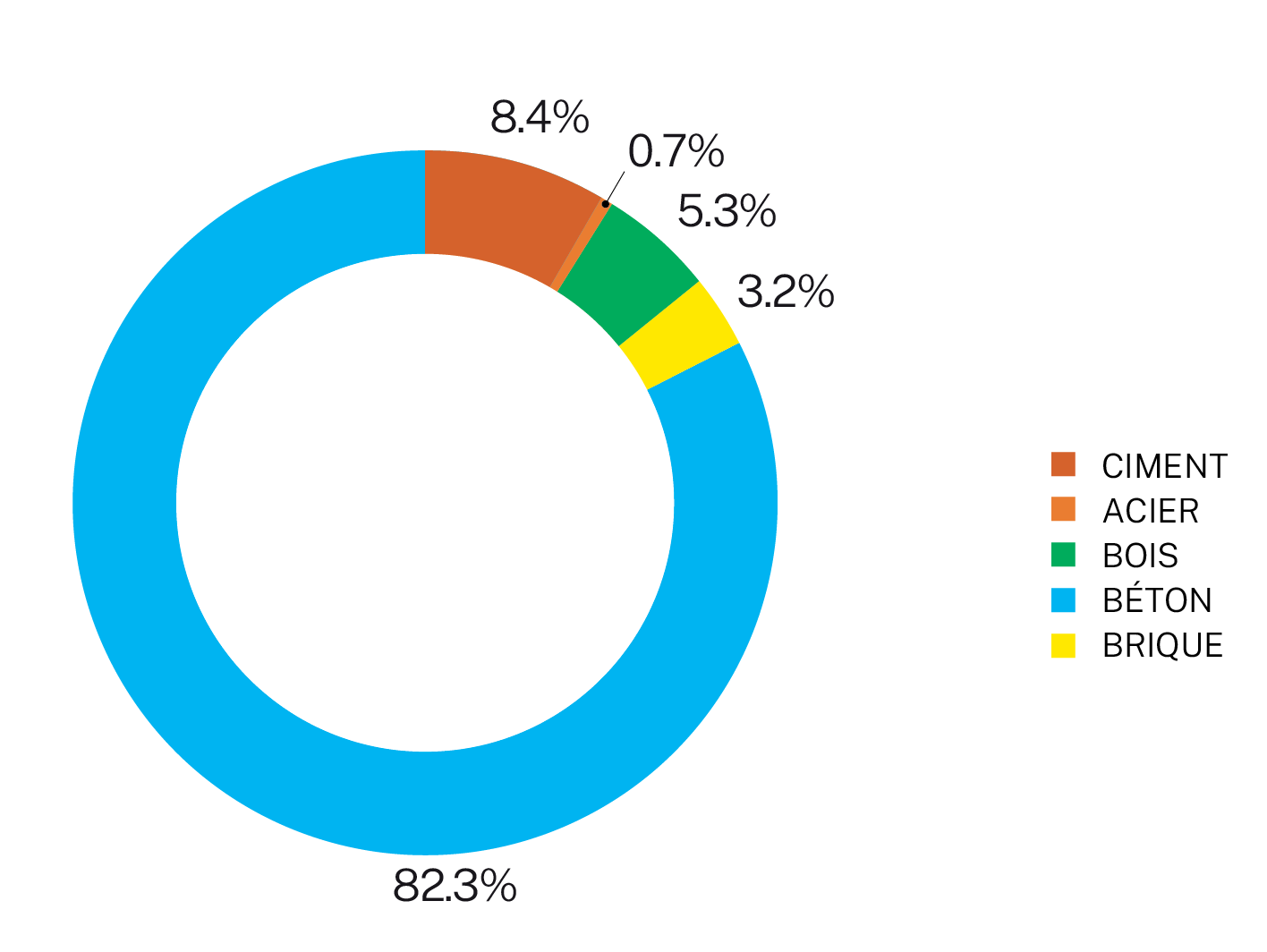

In Switzerland, approximately forty million tons of concrete are used every year[1], making it the dominant building material with over 80 percent market share.[2]

Despite its significant environmental cost, concrete remains unmatched in terms of performance and technical reliability. The structural frame of a new building accounts for about 40 percent of its total carbon footprint[3], especially the slabs, which are among the most challenging elements to decarbonize. While interest in circular and low-carbon solutions is growing, structural reuse of concrete remains rare. Most concrete is either crushed and reused as aggregate in new concrete—a process that does not address the cement-related emissions, which account for roughly 70 percent of its impact[4]or sent to landfill.

Solution

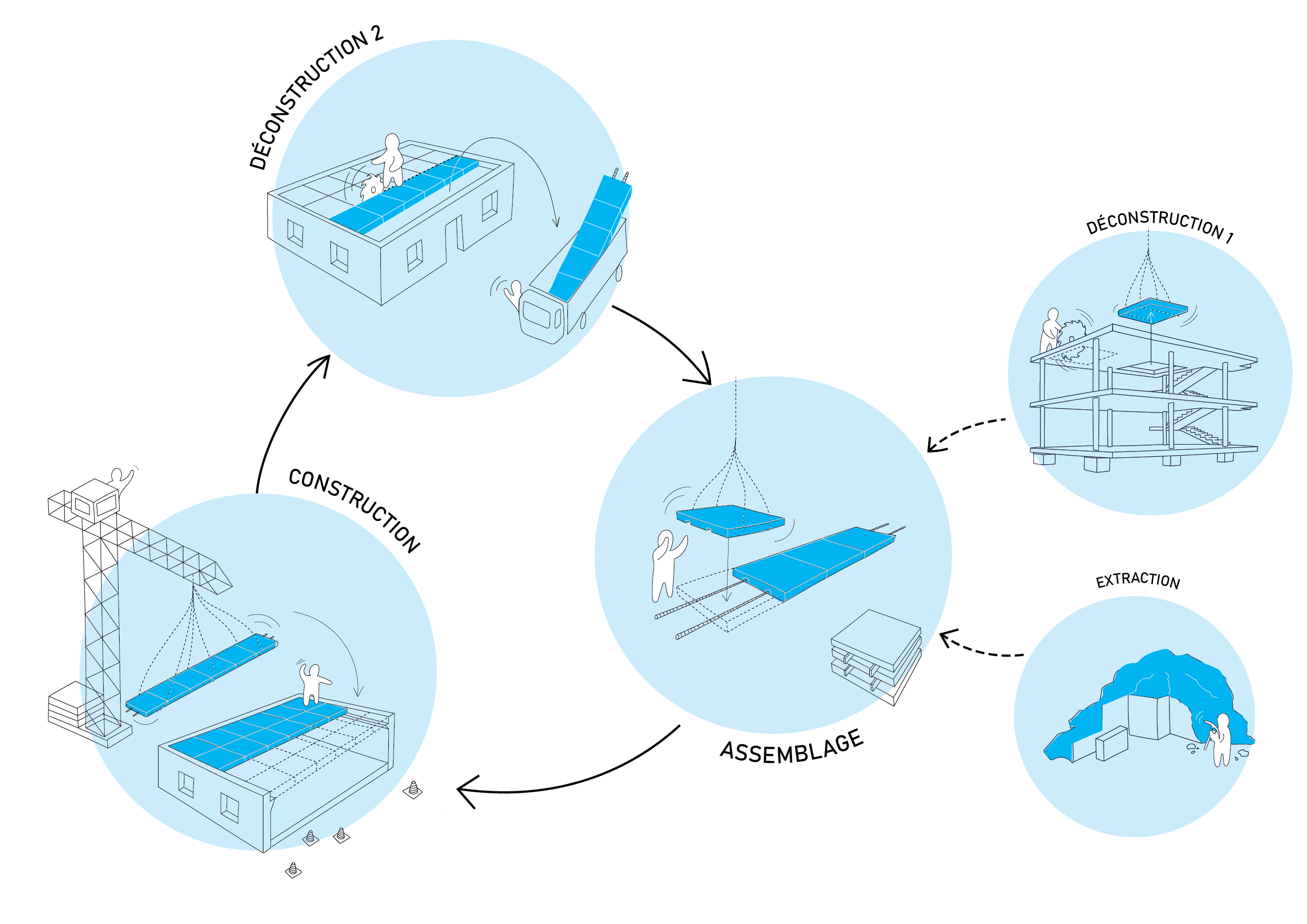

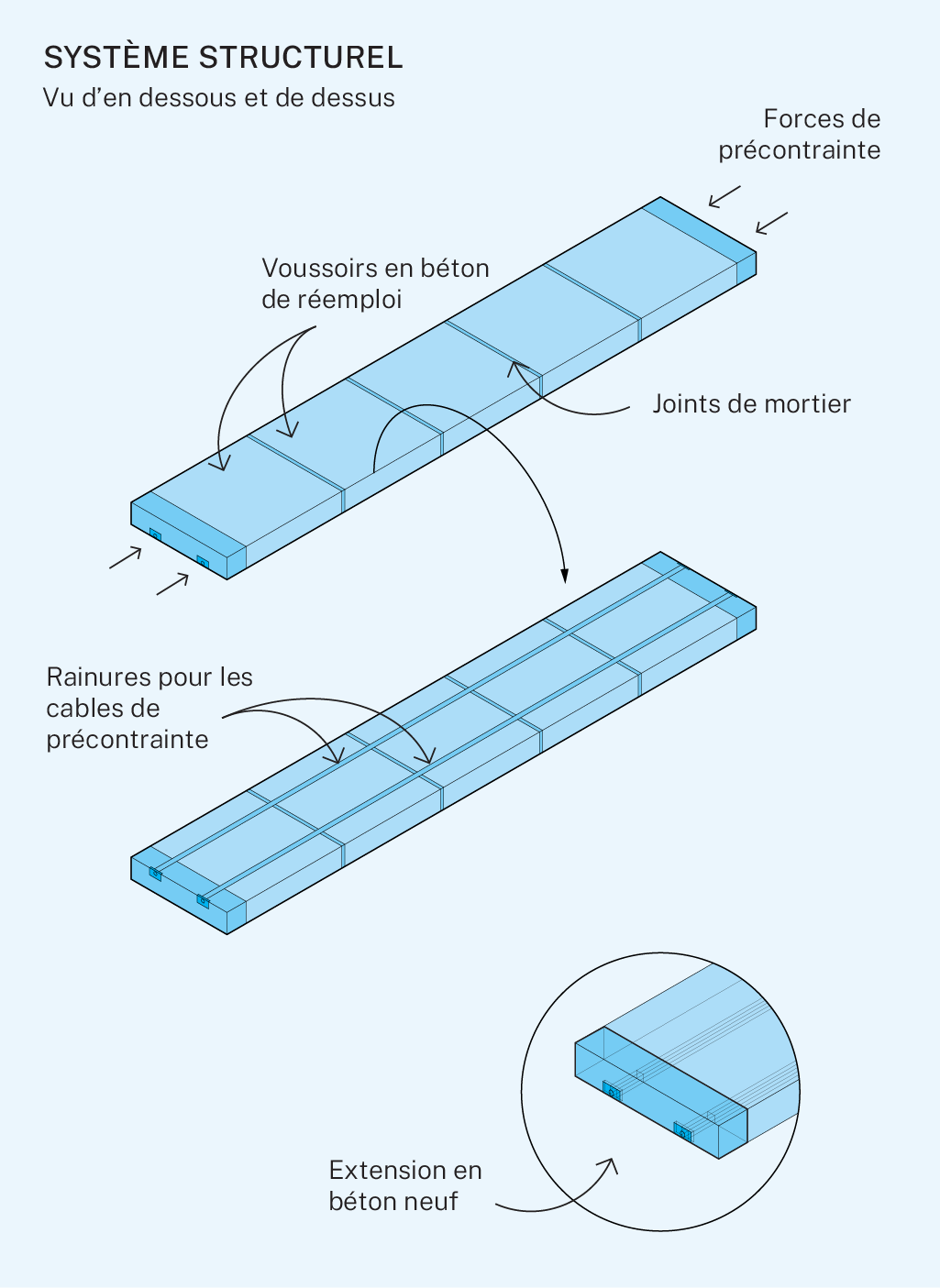

In collaboration with Cooperative 2401, VSL Switzerland, and Marti Construction, we developed an approach to avoid crushing concrete by directly using natural stone or reusing existing concrete: what if we cut, assembled, and prestressed low-carbon mineral elements sourced from quarries or deconstructed buildings to create a new modular slab system?

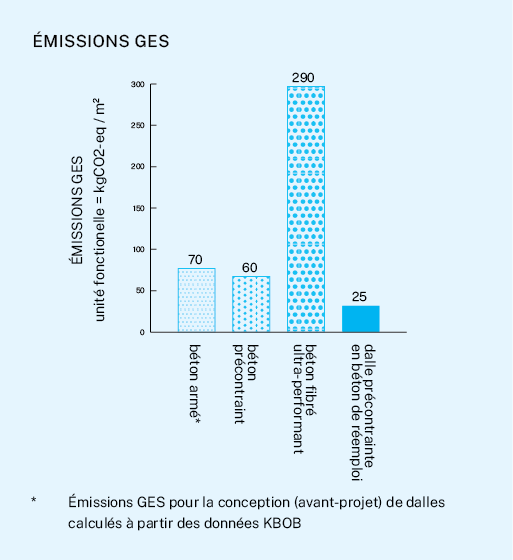

Thanks to the Viva project of the Canton of Vaud and the Circular Economy Support Fund (SPEI), the consortium was able to develop, produce, and test four prototypes: three prestressed segmental slabs made from reclaimed concrete and one from stone. The reclaimed concrete prototypes demonstrated superior mechanical performance (stiffness) compared to new reinforced concrete, achieving over 60% reduction in the slabs’ carbon footprint. This paves the way for circular, low-carbon, and resource-efficient construction.

The stone slab, for its part, takes advantage of the material’s high compressive strength, which can reach up to 180 MPa in some granites – well beyond what is required for concrete. However, since stone is anisotropic, its performance depends on the direction of the applied loads and requires specific analysis to prevent failure modes such as delamination along sedimentation planes.

What’s next?

Following successful technical outcomes, a validated proof of concept, and publication of the results in the CISBAT scientific article[5], the consortium is now developing a design guide for developers and designers, with the support of the Circular Building Industry Innovation Booster from InnoSuisse.

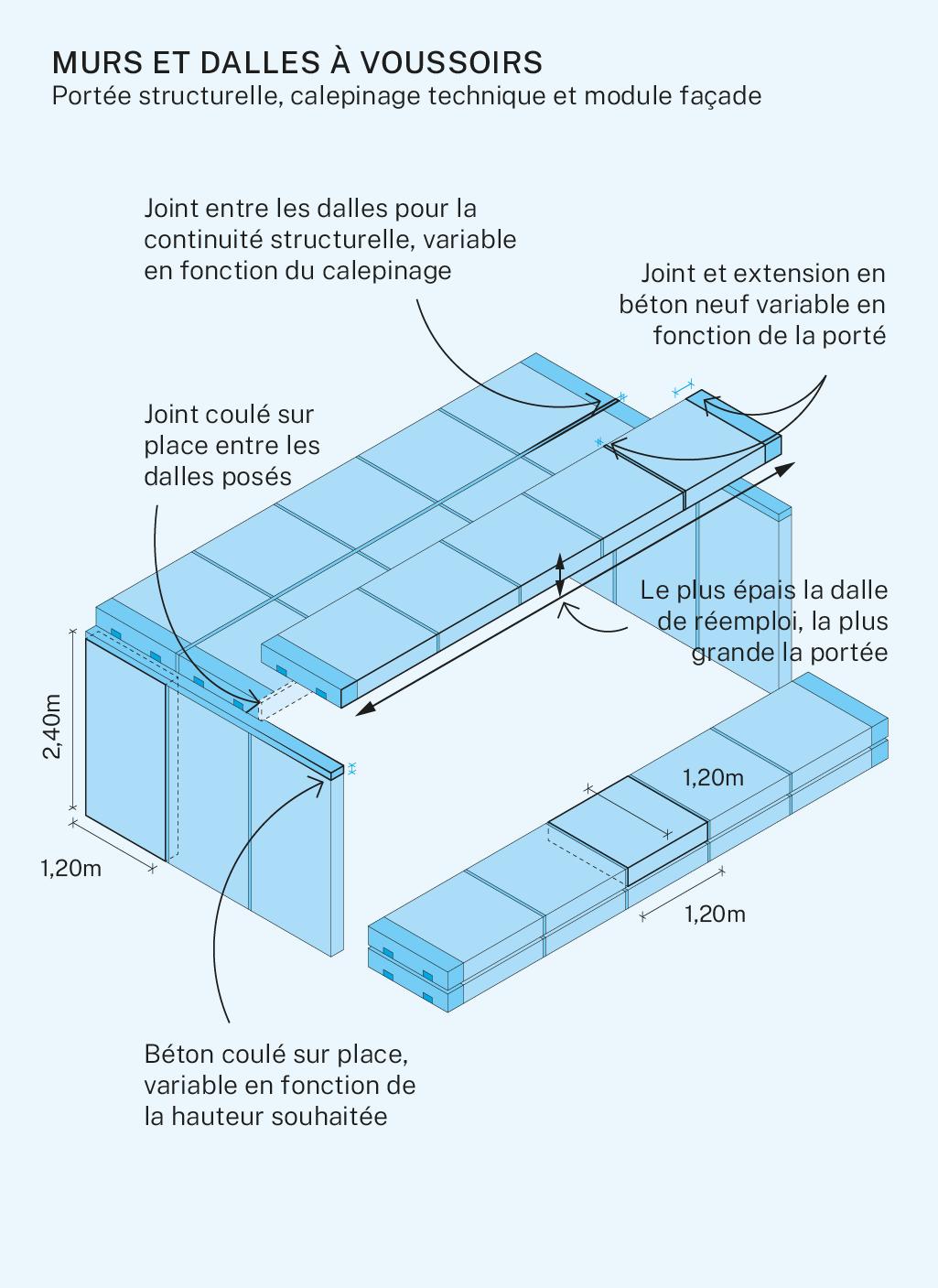

To address the technical and logistical challenges of deconstruction and reuse, the project proposes a standardized system for material extraction and preparation, inspired by proven construction methods. Elements are derived from a 2.4 m × 2.4 m module, shaped with grooves using simple tools such as a road saw and jackhammer, and then assembled and prestressed using standardized techniques. This standardization facilitates reproducibility and industrial scalability in line with circular construction principles.

Additional information

The project guide includes background and challenges, the proposed solution, project phases, stiffness and CO₂ results, and more.

Download the project guide (PDF) (2.6 MB)

Download the project guide (PDF) (2.6 MB)

Sources

Habert G., Miller, S. A., John, V. M., Provis, J. L., A. Favier, A., Horvath, A., & Scrivener, K. L. (2020). Environmental impacts and decarbonization strategies in the cement and concrete industries. Nature Reviews: Earth & Environment, 1, 559-565. https://doi.org/10.1038/s43017-020-0093-3

Matasci, C., Gauch, M., Böni, H., & Wäger, P. (2021). The Influence of Consumer Behavior on Climate Change: The Case of Switzerland. Sustainability 2021, 13 (2966). https://doi.org/10.3390/su13052966

Pathé, J., Gilbert, P. L., Schirmer, R,. Lasvaux, S., & Paquier, A. (2025). Prestressed segmental slabs in reclaimed concrete or stone: a systemic and effective solution for sustainable floors. Journal of Physics: Conference Series 3140 (2025) 162006. https://doi.org/10.1088/1742-6596/3140/16/162006

Société Suisse des Entrepreneurs SSE. (2021). Étude sur les matériaux de construction utilisés en Suisse. Société Suisse des Entrepreneurs SSE Politique et Communication. https://shop.baumeister.ch/shop/document_download.php?document=%C3%89tude_mat%C3%A9riaux-de-construction_web_FR.pdf

Contact

For any questions about integrating sustainability into your projects, feel free to reach out to our sustainability experts at: sustainability@ittenbrechbuehl.ch.